Njengoko ubuchwepheshe be-laser enamandla aphezulu buqhubeka nokuqhubela phambili ngokukhawuleza, iiLaser Diode Bars (iiLDB) ziye zasetyenziswa kakhulu kwimizi-mveliso, utyando lwezonyango, iLiDAR, kunye nophando lwesayensi ngenxa yobuninzi bazo bamandla aphezulu kunye nokukhanya okuphezulu. Nangona kunjalo, ngokuhlanganiswa okwandayo kunye nomsinga wokusebenza weetships ze-laser, imingeni yolawulo lobushushu iya isanda—ichaphazela ngokuthe ngqo uzinzo lokusebenza kunye nobomi be-laser.

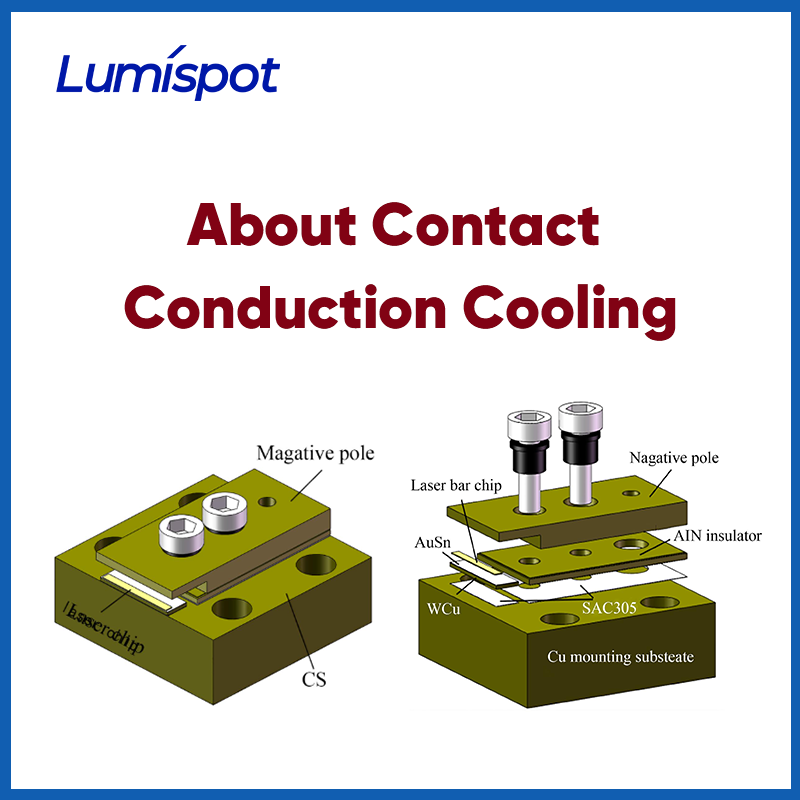

Phakathi kweendlela ezahlukeneyo zokulawula ubushushu, i-Contact Conducting Cooling ivelele njengenye yezona ndlela zibalulekileyo nezamkelweyo ngokubanzi ekupakisheni iibha ze-laser diode, ngenxa yesakhiwo sayo esilula kunye nokuqhuba okuphezulu kobushushu. Eli nqaku liphonononga imigaqo, izinto ezibalulekileyo eziqwalaselweyo kuyilo, ukukhethwa kwezinto, kunye neendlela zexesha elizayo zale "ndlela izolileyo" yokulawula ubushushu.

1. Imigaqo yokuPholisa ukuQokelelwa koQhagamshelo

Njengoko igama lisitsho, ukupholisa ukuhanjiswa koqhagamshelwano kusebenza ngokuseka unxibelelwano oluthe ngqo phakathi kwe-laser chip kunye nesinki yobushushu, okuvumela ukudluliselwa kobushushu ngokufanelekileyo ngokusebenzisa izixhobo zokuhambisa ubushushu eziphezulu kunye nokusasazwa ngokukhawuleza kwindawo yangaphandle.

①The HyityaPath:

Kwibha ye-laser diode eqhelekileyo, indlela yobushushu yile ilandelayo:

Itshiphu → Umaleko weSolder → Ukuxhoma (umz., ubhedu okanye iseramikhi) → I-TEC (i-Thermoelectric Cooler) okanye i-Heat Sink → Indawo engqongileyo

②Iimbonakalo:

Le ndlela yokupholisa ineempawu ezilandelayo:

Ukuhamba kobushushu obuqinileyo kunye nendlela emfutshane yobushushu, kunciphisa ngempumelelo ubushushu bokuhlangana; Uyilo oluncinci, olufanelekileyo kwiipakethe ezincinci; Ukuhanjiswa okungasebenziyo, okufuna iiluphu zokupholisa ezisebenzayo ezintsonkothileyo.

2. Izinto ezibalulekileyo ekufuneka ziqwalaselwe kuyilo lokusebenza kobushushu

Ukuqinisekisa ukupholisa okusebenzayo kokuhanjiswa koqhagamshelwano, le miba ilandelayo kufuneka ijongwe ngononophelo ngexesha loyilo lwesixhobo:

① Ukumelana nobushushu kwi-Solder Interface

Ukuqhuba kobushushu komaleko we-solder kudlala indima ebalulekileyo ekuxhathiseni ubushushu ngokubanzi. Iintsimbi ezine-conductivity ephezulu ezifana ne-AuSn alloy okanye i-indium ecocekileyo kufuneka zisetyenziswe, kwaye ubukhulu kunye nokufana komaleko we-solder kufuneka kulawulwe ukunciphisa imiqobo yobushushu.

② Ukukhetha Izinto Ezingaphantsi KweeNqanaba

Izinto eziqhelekileyo ezisetyenziswa phantsi komhlaba ziquka:

I-Copper (Cu): Ukuqhuba ubushushu obuphezulu, kuyabiza kakhulu;

I-Tungsten Copper (WCu)/i-Molybdenum Copper (MoCu): I-CTE ihambelana ngcono neetships, inika amandla kunye nokuqhuba;

I-Aluminium Nitride (AlN): I-insulation yombane egqwesileyo, efanelekileyo kwii-voltage eziphezulu.

③ Umgangatho woQhagamshelwano lomphezulu

Uburhabaxa bomphezulu, ukuba tyaba, kunye nokufuma kuchaphazela ngokuthe ngqo ukusebenza kakuhle kokudluliselwa kobushushu. Ukupolisha kunye negolide kudla ngokusetyenziswa ukuphucula ukusebenza koqhagamshelwano lobushushu.

④ Ukunciphisa Indlela Yobushushu

Uyilo lwesakhiwo lufanele lujolise ekufinyezeni indlela yobushushu phakathi kwetshiphusi kunye nesinki yobushushu. Kuphephe iileya zezinto eziphakathi ezingafunekiyo ukuphucula ukusebenza kakuhle kokusasazwa kobushushu.

3. Imiyalelo yoPhuhliso lweXesha elizayo

Njengoko kukho umkhwa oqhubekayo wokwenza izinto zibe lula kunye nobuninzi bamandla, iteknoloji yokupholisa ukuhanjiswa koqhagamshelwano iyavela ngale ndlela ilandelayo:

① Ii-TIM ezidityanisiweyo ezinamaleko amaninzi

Ukudibanisa ukuhanjiswa kobushushu besinyithi kunye ne-flexible buffering ukunciphisa ukumelana kwe-interface kunye nokuphucula ukuqina kokujikeleza kobushushu.

② Ukupakisha i-Heat Sink edibeneyo

Ukuyila ii-submounts kunye nee-heat sinks njengesakhiwo esinye esidibeneyo sokunciphisa i-contact interfaces kunye nokwandisa ukusebenza kakuhle kokudluliselwa kobushushu kwinqanaba lenkqubo.

③ Ukulungiswa koBume beBionic

Ukusebenzisa iindawo ezakhiwe nge-microstructure ezilinganisa iindlela zendalo zokusasaza ubushushu—ezifana “nokuqhuba okufana nomthi” okanye “iipateni ezifana nesikali”—ukuphucula ukusebenza kobushushu.

④ Ulawulo oluBukrelekrele loBushushu

Ukubandakanya izinzwa zobushushu kunye nolawulo lwamandla oluguqukayo lolawulo lobushushu oluhambelanayo, nto leyo eyandisa ubomi bokusebenza kwesixhobo.

4. Isiphelo

Kwimivalo ye-laser diode enamandla aphezulu, ulawulo lobushushu aluyongxaki yobuchwephesha nje kuphela—lusisiseko esibalulekileyo sokuthembeka. Ukupholisa ukuhanjiswa koqhagamshelwano, kunye neempawu zalo ezisebenzayo, ezivuthiweyo, nezingabizi kakhulu, kusesesinye sezisombululo eziphambili zokusasaza ubushushu namhlanje.

5. Ngathi

Apha eLumispot, sizisa ubuchule obunzulu ekupakisheni i-laser diode, uvavanyo lolawulo lobushushu, kunye nokukhetha izixhobo. Injongo yethu kukubonelela ngezisombululo ze-laser ezisebenzayo nezihlala ixesha elide ezilungiselelwe iimfuno zakho zesicelo. Ukuba ungathanda ukufunda okungakumbi, siyakwamkela ngokufudumeleyo ukuba unxibelelane neqela lethu.

Ixesha lokuthumela: Juni-23-2025