Bhalisela kwiMidiya yethu yeNtlalo ukuze ufumane iPosi ekhawulezileyo

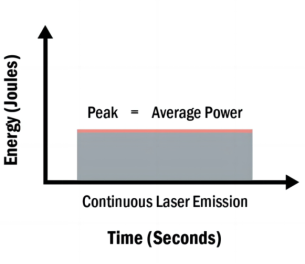

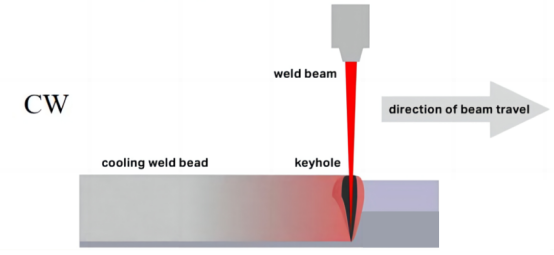

I-Laser yamaza eqhubekayo

I-CW, isifinyezo segama elithi "Continuous Wave," sibhekisa kwiinkqubo zelaser ezikwaziyo ukubonelela ngemveliso yelaser engaphazanyiswayo ngexesha lokusebenza. Zibonakaliswa kukukwazi kwazo ukukhupha ilaser ngokuqhubekayo de umsebenzi uyeke, iilaser ze-CW zahlulwe ngamandla azo aphantsi kunye namandla aphezulu aphakathi xa kuthelekiswa nezinye iintlobo zeelaser.

Izicelo ezibanzi

Ngenxa yendlela ezisebenza ngayo rhoqo, ii-laser ze-CW zisetyenziswa kakhulu kwiindawo ezifana nokusika isinyithi kunye nokuwelda ubhedu kunye ne-aluminium, nto leyo eyenza zibe phakathi kweentlobo ze-laser eziqhelekileyo nezisetyenziswa kakhulu. Ubuchule bazo bokuvelisa amandla azinzileyo nazinzileyo buzenza zibe luncedo kakhulu kwiimeko zokucubungula ngokuchanekileyo kunye nemveliso enkulu.

Iiparamitha zoLungiso lweNkqubo

Ukulungisa i-CW laser ukuze isebenze kakuhle inkqubo kubandakanya ukugxila kwiiparameters ezininzi ezibalulekileyo, kubandakanya i-power waveform, ubungakanani be-defocus, ububanzi be-beam spot, kunye nesantya sokucubungula. Ukulungiswa ngokuchanekileyo kwezi parameters kubalulekile ekufezekiseni iziphumo ezilungileyo zokucubungula, ukuqinisekisa ukusebenza kakuhle kunye nomgangatho kwimisebenzi yokulungisa i-laser.

Umzobo wamandla eLaser oqhubekayo

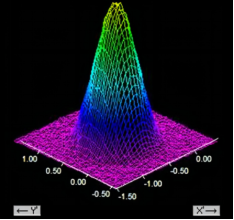

Iimpawu zoSasazo lwaMandla

Uphawu oluphawulekayo lwee-laser ze-CW kukusasazwa kwamandla e-Gaussian, apho ukusasazwa kwamandla kwecandelo elinqamlezileyo le-laser beam kuncipha ukusuka embindini ukuya ngaphandle kwipateni ye-Gaussian (ukusasazwa okuqhelekileyo). Olu phawu lokusasazwa luvumela ii-laser ze-CW ukuba zifezekise ukuchaneka okuphezulu kakhulu kokugxila kunye nokusebenza kakuhle kokucubungula, ingakumbi kwizicelo ezifuna ukusasazwa kwamandla aqinileyo.

Umzobo woSasazo lwaMandla eLaser yeCW

Iingenelo ze-Continuous Wave (CW) Laser Welding

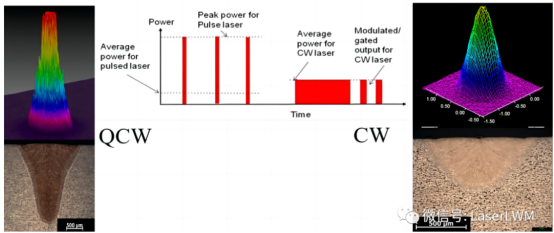

Imbono yeZinto ezincinci

Ukuhlola ulwakhiwo lwesinyithi oluncinci kutyhila iingenelo ezahlukeneyo zokufakelwa kwe-laser ye-Continuous Wave (CW) ngaphezu kokufakelwa kwe-pulse ye-Quasi-Continuous Wave (QCW). Ukufakelwa kwe-pulse ye-QCW, okuthintelwe ngumda wayo we-frequency, oqhele ukuba malunga ne-500Hz, kujongana notshintsho phakathi kwesantya sokufakelwa kunye nobunzulu bokungena. Isantya esiphantsi sokufakelwa kwe-interlapse sibangela ubunzulu obungonelanga, ngelixa isantya sokufakelwa kwe-interlapse esiphezulu sithintela isantya sokufakelwa kwe-welding, kunciphisa ukusebenza kakuhle. Ngokwahlukileyo koko, ukufakwa kwe-laser ye-CW, ngokukhetha ububanzi bee-core ze-laser ezifanelekileyo kunye neentloko zokufakelwa kwe-welding, kufezekisa ukudityaniswa okusebenzayo nokuqhubekayo. Le ndlela ingqineka ithembekile ngakumbi kwizicelo ezifuna ukuthembeka okuphezulu kwe-seal.

Ukuqwalaselwa kweMpembelelo yoBushushu

Ngokwembono yempembelelo yobushushu, i-QCW pulse laser welding inengxaki yokudibana, nto leyo ekhokelela ekufudumaleni okuphindaphindiweyo komthungo we-weld. Oku kunokubangela ukungangqinelani phakathi kwesakhiwo sesinyithi kunye nezinto ezisisiseko, kubandakanya umahluko kubungakanani bokuqhekeka kunye namazinga okupholisa, ngaloo ndlela kwandisa umngcipheko wokuqhekeka. I-CW laser welding, kwelinye icala, iyayiphepha le ngxaki ngokubonelela ngenkqubo yokufudumeza efanayo neqhubekayo.

Uhlengahlengiso olulula

Ngokuphathelele ukusebenza kunye nokulungiswa, i-QCW laser welding ifuna ukulungiswa ngononophelo kweeparameter ezininzi, kubandakanya i-pulse repetition frequency, amandla aphezulu, ububanzi be-pulse, umjikelo womsebenzi, nokunye. I-CW laser welding yenza lula inkqubo yohlengahlengiso, igxile kakhulu kwi-waveform, isantya, amandla, kunye nobungakanani be-defocus, nto leyo eyenza kube lula kakhulu ukusebenza.

Inkqubela phambili kwezobuchwepheshe kwi-CW Laser Welding

Nangona i-QCW laser welding yaziwa ngamandla ayo aphezulu kunye nokufakwa okuphantsi kobushushu, iluncedo kwiinxalenye ezibuthathaka kubushushu kunye nezinto ezixineneyo kakhulu, inkqubela phambili kwitekhnoloji ye-CW laser welding, ngakumbi kwizicelo zamandla aphezulu (ngesiqhelo ngaphezulu kwama-watts angama-500) kunye ne-deep penetration welding ngokusekelwe kwisiphumo se-keyhole, yandise kakhulu uluhlu lwayo lokusebenza kunye nokusebenza kakuhle. Olu hlobo lwe-laser lufanelekile ngokukodwa kwizixhobo ezijiyileyo kune-1mm, lufikelela kwimilinganiselo ephezulu (ngaphezulu kwe-8:1) nangona kufakwe ubushushu obuphezulu.

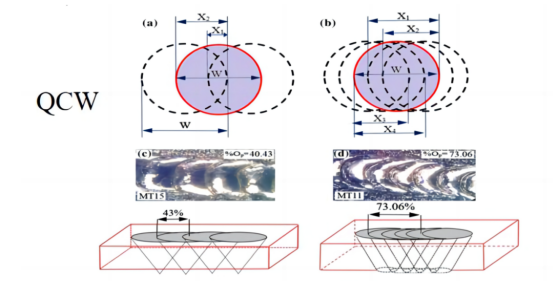

Ukuwelda kweLaser yeQuasi-Continuous Wave (QCW)

Ukusasazwa kwamandla agxile

I-QCW, emele "i-Quasi-Continuous Wave," imele iteknoloji yelaser apho i-laser ikhupha ukukhanya ngendlela engaqhubekiyo, njengoko kuboniswe kumfanekiso a. Ngokungafaniyo nokusasazwa kwamandla okufanayo kwe-single-mode continuous lasers, ii-QCW lasers zigxila amandla azo ngokuxineneyo. Olu phawu lunika ii-QCW lasers uxinano lwamandla oluphezulu, oluguqulela ekubeni namandla okungena aqine ngakumbi. Isiphumo se-metallurgical esiphumelayo sifana nesimo "sesikhonkwane" esinomlinganiselo obalulekileyo wobunzulu nobubanzi, okuvumela ii-QCW lasers ukuba zigqwese kwizicelo ezibandakanya ii-alloys ezibonisa ukukhanya okuphezulu, izinto ezinobuthathaka kubushushu, kunye ne-precision micro-welding.

Uzinzo Oluphuculweyo kunye Nokuphazamiseka Okuncitshisiweyo KweePlume

Enye yeenzuzo ezicacileyo ze-QCW laser welding kukukwazi kwayo ukunciphisa imiphumo ye-metal plume kwisantya sokufunxwa kwezinto, nto leyo ekhokelela kwinkqubo ezinzileyo ngakumbi. Ngexesha lokusebenzisana kwezinto ze-laser, ukufuma okukhulu kunokudala umxube womphunga wesinyithi kunye ne-plasma ngaphezulu kwedama elinyibilikayo, elibizwa ngokuba yi-metal plume. Le plume inokukhusela umphezulu wezinto kwi-laser, ibangele ukuhanjiswa kwamandla okungazinzi kunye neziphene ezifana nokutshiza, iindawo zokuqhuma, kunye nemingxunya. Nangona kunjalo, ukukhutshwa okukhawulezileyo kwe-QCW lasers (umz., ukuqhuma kwe-5ms kulandelwa kukumiswa kwe-10ms) kuqinisekisa ukuba i-laser pulse nganye ifikelela kumphezulu wezinto ingachaphazeleki yi-metal plume, nto leyo ekhokelela kwinkqubo yokuwelda eqinileyo, ingakumbi eluncedo kwi-thin-sheet welding.

IiDynamics zeChibi leStable Melt

Iindlela ezitshintshatshintsha ngayo ichibi lokunyibilika, ingakumbi ngokubhekiselele kumandla asebenza kwisitshixo, zibalulekile ekumiseleni umgangatho we-weld. Iilaser eziqhubekayo, ngenxa yokuvezwa kwazo ixesha elide kunye neendawo ezinkulu ezichaphazeleka bubushushu, zivame ukudala amachibi amakhulu okunyibilika azaliswe yintsimbi engamanzi. Oku kunokukhokelela kwiziphene ezinxulumene namachibi amakhulu okunyibilika, njengokuwa kwesitshixo. Ngokwahlukileyo koko, amandla agxileyo kunye nexesha elifutshane lokusebenzisana kwe-QCW laser welding zigxila ichibi lokunyibilika elijikeleze isitshixo, nto leyo ebangela ukusasazwa kwamandla okufanayo kunye nokwehla kwe-porosity, ukuqhekeka, kunye nokuchitheka.

Indawo Echaphazeleka Bubushushu Encitshisiweyo (HAZ)

Ukuwelda nge-laser okuqhubekayo kubeka izinto kubushushu obuhlala ixesha elide, nto leyo ekhokelela ekuhanjisweni okukhulu kobushushu kwizinto. Oku kunokubangela ukuguquguquka kobushushu okungafunekiyo kunye neziphene ezibangelwa luxinzelelo kwizinto ezincinci. Ii-laser ze-QCW, ngokusebenza kwazo okwethutyana, zivumela izinto ukuba ziphole ixesha elide, ngaloo ndlela zinciphisa indawo echaphazelekileyo bubushushu kunye nokufakwa kobushushu. Oku kwenza ukuwelda nge-laser ye-QCW kulunge ngakumbi kwizinto ezincinci kunye nezo zikufutshane nezinto ezinobushushu.

Amandla aphezulu eNqanaba

Nangona zinamandla aphakathi afanayo nee-laser eziqhubekayo, ii-laser ze-QCW zifikelela kumandla aphezulu kunye noxinano lwamandla, nto leyo ebangela ukungena okunzulu kunye nokukwazi ukuwelda okunamandla. Le nzuzo ibonakala ngakumbi ekuwelding amaphepha amancinci e-copper kunye ne-aluminium alloys. Ngokwahlukileyo koko, ii-laser eziqhubekayo ezinamandla aphakathi afanayo zinokungaphumeleli ukwenza uphawu kumphezulu wezinto ngenxa yoxinano lwamandla oluphantsi, nto leyo ekhokelela ekukhanyeni. Ii-laser eziqhubekayo ezinamandla aphezulu, nangona zikwazi ukunyibilikisa izinto, zinokufumana ukunyuka okukhulu kwinqanaba lokufunxa emva kokunyibilika, okubangela ubunzulu bokunyibilika obungalawulekiyo kunye nokufakwa kobushushu, okungafanelekiyo kwi-thin-sheet welding kwaye kunokubangela ukuba kungabikho maki okanye ukutsha, ukungaphumeleli ukuhlangabezana neemfuno zenkqubo.

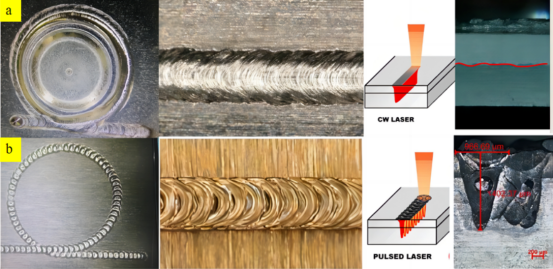

Ukuthelekiswa kweziphumo zokuwelda phakathi kwe-CW kunye ne-QCW lasers

a. I-Laser ye-Continuous Wave (CW):

- Inkangeleko yesikhonkwane esivalwe nge-laser

- Inkangeleko yomthungo othe tye weld

- Umzobo wesicwangciso sokukhutshwa kwelaser

- Icandelo elinqamlezileyo le-longitudinal

b. I-Laser ye-Quasi-Continuous Wave (QCW):

- Inkangeleko yesikhonkwane esivalwe nge-laser

- Inkangeleko yomthungo othe tye weld

- Umzobo wesicwangciso sokukhutshwa kwelaser

- Icandelo elinqamlezileyo le-longitudinal

- * Umthombo: Inqaku likaWilldong, nge-WeChat Public Account LaserLWM.

- * Ikhonkco lenqaku lokuqala: https://mp.weixin.qq.com/s/8uCC5jARz3dcgP4zusu-FA.

- Umxholo wale nqaku ulungiselelwe iinjongo zokufunda nokunxibelelana kuphela, kwaye lonke ilungelo lokushicilela lelombhali wokuqala. Ukuba kukho ukwaphulwa kwelungelo lokushicilela, nceda unxibelelane nathi ukuze ususe.

I-QCW Laser evela kwiLumispot Tech:

Ileyiza yeCW:

Ixesha lokuthumela: Matshi-05-2024