Bhalisela kwiMidiya yethu yeNtlalo ukuze ufumane iPosi ekhawulezileyo

Intshayelelo kwi-Laser Processing kwi-Manufacturing

Itekhnoloji yokucubungula i-laser iye yaphuhliswa ngokukhawuleza kwaye isetyenziswa kakhulu kwiinkalo ezahlukeneyo, ezifana neenqwelo-moya, iimoto, izixhobo ze-elektroniki, nokunye. Idlala indima ebalulekileyo ekuphuculeni umgangatho wemveliso, imveliso yabasebenzi, kunye nokusebenza ngokuzenzekelayo, ngelixa inciphisa ungcoliseko kunye nokusetyenziswa kwezinto (Gong, 2012).

Ukucutshungulwa kweLaser kwiZixhobo zeMetal kunye nezingezizo zeMetal

Ukusetyenziswa okuphambili kokucubungula nge-laser kwiminyaka elishumi edlulileyo bekukwizinto zesinyithi, kubandakanya ukusika, ukuwelda, kunye nokugquma. Nangona kunjalo, eli candelo liya lisanda ukuya kwizinto ezingezizo zesinyithi ezifana neempahla zelaphu, iglasi, iiplastiki, iipolymers, kunye neeseramikhi. Ngayinye kwezi zinto ivula amathuba kumashishini ahlukeneyo, nangona sele benazo iindlela zokucubungula ezisemgangathweni (Yumoto et al., 2017).

Imingeni kunye noBuchule kwi-Laser Processing yeGlasi

Iglasi, enezicelo zayo ezibanzi kumashishini afana neemoto, ulwakhiwo, kunye ne-elektroniki, imele indawo ebalulekileyo yokucubungula nge-laser. Iindlela zemveli zokusika iglasi, ezibandakanya izixhobo ze-alloy eqinileyo okanye zedayimani, zithintelwe kukusebenza okuphantsi kunye nemiphetho erhabaxa. Ngokwahlukileyo koko, ukusika nge-laser kunika enye indlela esebenza kakuhle nechanekileyo. Oku kubonakala ngakumbi kumashishini afana nokuvelisa ii-smartphone, apho ukusika nge-laser kusetyenziswa kwiikhava zelensi zekhamera kunye nezikrini ezinkulu zokubonisa (Ding et al., 2019).

Ukucutshungulwa kweLaser kweeNtlobo zeGlasi eziBalulekileyo kakhulu

Iindidi ezahlukeneyo zeglasi, njengeglasi ye-optical, iglasi ye-quartz, kunye neglasi ye-sapphire, zinemingeni eyahlukileyo ngenxa yokuba zibuthathaka. Nangona kunjalo, iindlela eziphambili ze-laser ezifana ne-femtosecond laser etching ziye zavumela ukucutshungulwa ngokuchanekileyo kwezi zinto (Sun & Flores, 2010).

Impembelelo yeWavelength kwiinkqubo zobuchwepheshe beLaser

Ubude be-laser buyichaphazela kakhulu le nkqubo, ingakumbi kwizinto ezifana nentsimbi yesakhiwo. Iilaser ezikhupha kwiindawo ze-infrared ezikhanyayo, ezibonakalayo, ezikufutshane nezikude ziye zahlalutywa ngenxa yobuninzi bazo bamandla okunyibilikisa nokuphuma komphunga (Lazov, Angelov, & Teirumnieks, 2019).

Izicelo ezahlukeneyo ezisekelwe kwi-Wavelengths

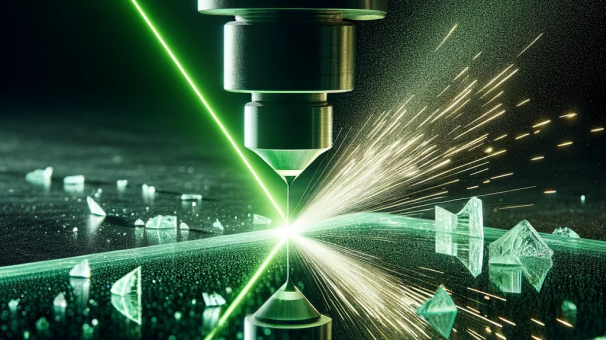

Ukukhetha ubude be-laser abuxhomekekanga kodwa kuxhomekeke kakhulu kwiimpawu zezinto kunye nesiphumo esifunekayo. Umzekelo, ii-UV lasers (ezinama-wavelength amafutshane) zilungile kakhulu ekukroleni ngokuchanekileyo kunye nokwenza i-micromachining, njengoko zinokuvelisa iinkcukacha ezicokisekileyo. Oku kuzenza zilungele amashishini e-semiconductor kunye ne-microelectronics. Ngokwahlukileyo koko, ii-infrared lasers zisebenza kakuhle ngakumbi ekucutshungulweni kwezinto ezixineneyo ngenxa yamandla azo okungena nzulu, nto leyo ezenza zifaneleke kwizicelo zemizi-mveliso enzima. (Majumdar & Manna, 2013). Ngokufanayo, ii-green lasers, ezihlala zisebenza kumaza angama-532 nm, zifumana indawo yazo kwizicelo ezifuna ukuchaneka okuphezulu kunye nefuthe elincinci lobushushu. Zisebenza ngakumbi kwi-microelectronics kwimisebenzi efana nokucwangcisa iisekethe, kwizicelo zonyango kwiinkqubo ezifana ne-photocoagulation, nakwicandelo lamandla ahlaziyekayo ekwenziweni kweeseli zelanga. Ububanzi be-wavelength obukhethekileyo bee-green lasers bukwenza zifaneleke ukumaka nokukrola izixhobo ezahlukeneyo, kubandakanya iiplastiki kunye neesinyithi, apho kufuneka umahluko omkhulu kunye nomonakalo omncinci womphezulu. Oku kulungelelaniswa kwee-green lasers kugxininisa ukubaluleka kokukhethwa kwamaza kwitekhnoloji ye-laser, ukuqinisekisa iziphumo ezilungileyo kwizixhobo ezithile kunye nezicelo.

II-laser eluhlaza eyi-525nmluhlobo oluthile lobuchwepheshe be-laser olubonakaliswa kukukhanya kwayo okuluhlaza okwahlukileyo kubude be-525 nanometers. Ii-laser eziluhlaza kule ubude be-wavelength zifumana ukusetyenziswa kwi-retina photocoagulation, apho amandla azo aphezulu kunye nokuchaneka kuluncedo. Zikwaluncedo ekucutshungulweni kwezinto, ngakumbi kwiindawo ezifuna ukucutshungulwa okuchanekileyo nokuncinci kobushushu..Uphuhliso lwee-diode ze-laser eziluhlaza kwi-c-plane GaN substrate ukuya kwii-wavelengths ezinde kwi-524–532 nm lubonisa inkqubela phambili ebalulekileyo kwitekhnoloji ye-laser. Olu phuhliso lubalulekile kwizicelo ezifuna iimpawu ezithile ze-wavelength.

Imithombo yeLaser eqhubekekayo kunye neModelocked

I-Continuous wave (CW) kunye ne-modellocked quasi-CW laser sources kwii-wavelengths ezahlukeneyo ezifana ne-near-infrared (NIR) kwi-1064 nm, eluhlaza kwi-532 nm, kunye ne-ultraviolet (UV) kwi-355 nm zithathwa njengee-laser doping selective emitter solar cells. Ii-wavelengths ezahlukeneyo zinefuthe ekuzivumelaniseni nokuveliswa kunye nokusebenza kakuhle (Patel et al., 2011).

I-Excimer Lasers yezixhobo ze-Wide Band Gap

Iilaser ze-Excimer, ezisebenza kwi-UV wavelength, zifanelekile ekucubunguleni izinto ezibanzi ezifana neglasi kunye ne-carbon fiber-reinforced polymer (CFRP), ezibonelela ngocoselelo oluphezulu kunye nefuthe elincinci lobushushu (Kobayashi et al., 2017).

I-Nd:YAG Lasers yezicelo zemizi-mveliso

Iilaser ze-Nd:YAG, ezinokuzivumelanisa nezimo ngokwendlela yokulungisa ubude be-wavelength, zisetyenziswa kwiindlela ezahlukeneyo zokusebenza. Ubuchule bazo bokusebenza kwi-1064 nm kunye ne-532 nm buvumela ukuguquguquka ekucubunguleni izixhobo ezahlukeneyo. Umzekelo, ubude be-1064 nm bufanelekile ekukroleni nzulu kwiisinyithi, ngelixa ubude be-532 nm bubonelela ngokrolo oluphezulu oluphezulu kwiiplastiki nakwiisinyithi ezigqunyiweyo. (Moon et al., 1999).

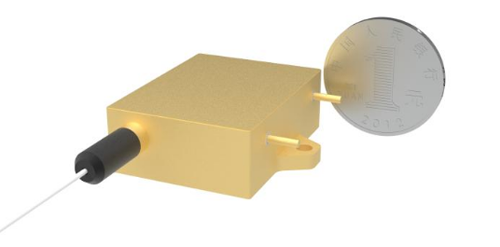

→Iimveliso eziNxulumeneyo:I-CW Diode-pumped solid-state laser ene-1064nm wavelength

Ukuwelda kweLaser yeFiber eneMandla aphezulu

Iilaser ezine-wavelengths ezikufutshane ne-1000 nm, ezinomgangatho olungileyo we-beam kunye namandla aphezulu, zisetyenziswa kwi-keyhole laser welding yeentsimbi. Ezi laser zinyibilikisa kwaye zinyibilikise izinto ngokufanelekileyo, zivelise ii-welds ezikumgangatho ophezulu (Salminen, Piili, & Purtonen, 2010).

Ukuhlanganiswa koLungiso lweLaser kunye nezinye iiTekhnoloji

Ukuhlanganiswa kokucubungula nge-laser nezinye iiteknoloji zokwenza izinto, ezifana ne-cladding kunye ne-milling, kukhokelele kwiinkqubo zemveliso ezisebenzayo neziguquguqukayo. Olu kuhlanganiswa luluncedo ngakumbi kumashishini afana nokuvelisa izixhobo kunye needayi kunye nokulungisa iinjini (Nowotny et al., 2010).

Ukucutshungulwa kweLaser kwiiNdawo eziPhumayo

Ukusetyenziswa kwetekhnoloji yelaser kufikelela kwiinkalo ezisakhasayo ezifana ne-semiconductor, i-display, kunye ne-thin film industry, okubonelela ngezakhono ezintsha kunye nokuphucula iipropati zezinto, ukuchaneka kwemveliso, kunye nokusebenza kwesixhobo (Hwang et al., 2022).

Iindlela Zekamva Zokucubungula Nge-Laser

Uphuhliso lwexesha elizayo kubuchwepheshe bokucubungula i-laser lugxile kwiindlela ezintsha zokwenza izinto, ukuphucula iimpawu zemveliso, ubunjineli obudibeneyo bezinto ezininzi kunye nokuphucula iingenelo zoqoqosho kunye neenkqubo. Oku kubandakanya ukwenziwa ngokukhawuleza kwezakhiwo ezine-porosity elawulwayo, ukuwelda okuxutyiweyo, kunye nokusika amaphepha esinyithi nge-laser profile (Kukreja et al., 2013).

Itekhnoloji yokucubungula i-laser, enezicelo zayo ezahlukeneyo kunye notshintsho oluqhubekayo, ibumba ikamva lokuvelisa kunye nokucubungula izinto. Ukuguquguquka kwayo kunye nokuchaneka kwayo kuyenza ibe sisixhobo esibalulekileyo kumashishini ahlukeneyo, ityhala imida yeendlela zemveli zokuvelisa.

Lazov, L., Angelov, N., kunye noTeirumnieks, E. (2019). INDLELA YOKUQIKELELA OKUQALAYO KOXINANO LWAMANDLA OLUBALULEKILEYO KWIINKQUBO ZOBUCHULE BE-LASER.INDALO. IITEKNOLOJI. IZIXHOBO. Iinkqubo zeNgqungquthela yezeNzululwazi neyoBuchule yaMazwe ngaMazwe. Ikhonkco

UPatel, R., Wenham, S., Tjahjono, B., Hallam, B., Sugianto, A., kunye noBovatsek, J. (2011). Ukwenziwa kwesantya esiphezulu kweeLaser Doping Selective Emitter Solar Cells kusetyenziswa i-532nm Continuous Wave (CW) kunye neModelocked Quasi-CW Laser Sources.Ikhonkco

Kobayashi, M., Kakizaki, K., Oizumi, H., Mimura, T., Fujimoto, J., & Mizoguchi, H. (2017). DUV amandla aphezulu lasers processing for iglasi kunye CFRP.Ikhonkco

UMoon, H., Yi, J., Rhee, Y., Cha, B., Lee, J., kunye noKim, K.-S. (1999). Ukuphindaphinda kwe-intracavity esebenzayo kabini ukusuka kwi-diffusive reflector-type diode side-pumped Nd:YAG laser esebenzisa ikristale yeKTP.Ikhonkco

Salminen, A., Piili, H., & Purtonen, T. (2010). Iimpawu zamandla aphezulu we-fiber laser welding.Iingxelo zeZiko leeNjineli zooMatshini, iCandelo C: Ijenali yeSayensi yoBunjineli booMatshini, 224, 1019-1029.Ikhonkco

UMajumdar, J., kunye noManna, I. (2013). Intshayelelo kwiLaser Assisted Fabrication of Materials.Ikhonkco

UGong, S. (2012). Uphando kunye nokusetyenziswa kwetekhnoloji yokucubungula i-laser ephucukileyo.Ikhonkco

Yumoto, J., Torizuka, K., kunye noKuroda, R. (2017). Uphuhliso lweBhedi yoVavanyo lweLaser-Manufacturing kunye neDatabase yoLungiselelo lweLaser-Material.Uphononongo lweNjineli yeLaser, 45, 565-570.Ikhonkco

Ding, Y., Xue, Y., Pang, J., Yang, L.-j., & Hong, M. (2019). Ukuqhubela phambili kwitekhnoloji yokuhlola i-in-situ yokusetyenzwa kwe-laser.I-SCENTIA SINICA Physica, Mechanica & Astronomica. Ikhonkco

Sun, H., kunye noFlores, K. (2010). Uhlalutyo lweMicrstructural lweGlasi yesinyithi eSetyenziswe ngeLaser esekwe kwiZr.Iintengiselwano zeMetallurgical kunye nezixhobo A. Ikhonkco

UNowotny, S., Muenster, R., Schharek, S., kunye noBeyer, E. (2010). Iseli yelaser edibeneyo yokubopha kunye nokugaya ilaser edibeneyo.Ukwenziwa kwezinto ngokuzenzekelayo kwiNdibano, 30(1), 36-38.Ikhonkco

Kukreja, LM, Kaul, R., Paul, C., Ganesh, P., kunye noRao, BT (2013). Iindlela zokuCwangcisa izixhobo zeLaser eziPhumayo kwiZicelo zeShishini zexesha elizayo.Ikhonkco

Hwang, E., Choi, J., & Hong, S. (2022). Iinkqubo ezintsha zokukhupha umoya ezincediswa yilaser zokuvelisa ngokuchanekileyo nangokuphezulu.Isikali esincinci. Ikhonkco

Ixesha leposi: Jan-18-2024