| Isolder yokugquma Ii-Diode Laser Bar Stacks | I-AuSn ipakishwe |

| Ubude beWave ephakathi | 1064nm |

| Amandla okuphuma | ≥55W |

| Ukusebenza kwangoku | ≤30 A |

| I-Voltage yokusebenza | ≤24V |

| Indlela Yokusebenza | CW |

| Ubude boMngxunya | 900mm |

| Isibuko sokuphuma | T = 20% |

| Ubushushu bamanzi | 25±3℃ |

Bhalisela kwiMidiya yethu yeNtlalo ukuze ufumane iPosi ekhawulezileyo

Imfuno yeemodyuli ze-laser ezifakwe i-diode-pumped ze-CW (Continuous Wave) iyanda ngokukhawuleza njengomthombo obalulekileyo wokupompa kwii-laser ze-solid-state. Ezi modyuli zibonelela ngeenzuzo ezikhethekileyo zokuhlangabezana neemfuno ezithile zezicelo ze-laser ze-solid-state. I-G2 - I-Diode Pump Solid State Laser, imveliso entsha ye-CW Diode Pump Series evela kwi-LumiSpot Tech, inentsimi ebanzi yesicelo kunye nezakhono zokusebenza ezingcono.

Kule nqaku, siza kubandakanya umxholo ogxile kwizicelo zemveliso, iimpawu zemveliso, kunye neenzuzo zemveliso malunga ne-CW diode pump solid-state laser. Ekupheleni kwenqaku, ndiza kubonisa ingxelo yovavanyo lwe-CW DPL evela kwiLumispot Tech kunye neenzuzo zethu ezikhethekileyo.

Intsimi yesicelo

Iileyiza ze-semiconductor ezinamandla aphezulu zisetyenziswa kakhulu njengemithombo yepompo kwiileyiza ze-solid-state. Kwizicelo ezisebenzayo, umthombo we-semiconductor laser diode-pumping ubalulekile ekuphuculeni itekhnoloji ye-solid-state laser epomped diode.

Olu hlobo lwelaser lusebenzisa ilaser ye-semiconductor ene-fixed wavelength output endaweni yeKrypton okanye iXenon Lamp yendabuko ukupompa iikristale. Ngenxa yoko, le laser iphuculweyo ibizwa ngokuba yi-2ndukuveliswa kwe-CW pump laser (G2-A), eneempawu zokusebenza kakuhle, ubomi benkonzo ende, umgangatho olungileyo wemitha, uzinzo oluhle, ukuxinana kunye nokunciphisa amandla ombane.

Amandla Okumpompa Amandla Aphezulu

I-CW Diode Pump Source inika ukuqhuma okukhulu kwesantya samandla okukhanya, ipompa ngempumelelo i-gain medium kwi-solid-state laser, ukuze ifezekise ukusebenza okungcono kwe-solid-state laser. Kwakhona, amandla ayo aphezulu kakhulu (okanye amandla aphakathi) avumela uluhlu olubanzi lwezicelo kwiishishini, amayeza, kunye nesayensi.

Umqadi ogqwesileyo kunye nozinzo

Imodyuli yelaser yokupompa ye-CW semiconductor inomgangatho ogqwesileyo wokukhanya, kunye nozinzo oluzenzekelayo, nto leyo ebalulekileyo ekufezekiseni umbane ochanekileyo welaser olawulekayo. Ezi modyuli zenzelwe ukuvelisa iprofayili yelaser echazwe kakuhle nezinzileyo, ukuqinisekisa ukupompa okuthembekileyo nokungaguquguqukiyo kwelaser eqinileyo. Olu phawu luhlangabezana ngokugqibeleleyo neemfuno zokusetyenziswa kwelaser ekucutshungulweni kwezinto zoshishino, ukusika nge-laserkunye ne-R&D.

Ukusebenza Kwamaza Okuqhubekayo

Imo yokusebenza yeCW idibanisa zombini iingenelo ze-continuous wavelength laser kunye ne-Pulsed Laser. Umahluko ophambili phakathi kwe-CW Laser kunye ne-Pulsed laser kukuphuma kwamandla.CW I-laser, eyaziwa ngokuba yi-Continuous wave laser, ineempawu zendlela yokusebenza ezinzileyo kunye nokukwazi ukuthumela i-continuous wave.

Uyilo oluQhelekileyo nolunokuthenjwa

I-CW DPL inokudityaniswa ngokulula kwi-currenti-laser yesimo esiqinileyokuxhomekeke kuyilo oluncinci kunye nolwakhiwo. Ulwakhiwo lwazo oluqinileyo kunye nezixhobo ezikumgangatho ophezulu ziqinisekisa ukuthembeka kwexesha elide, zinciphisa iindleko zokungasebenzi kunye nokugcinwa, nto leyo ebaluleke kakhulu kwimveliso yemizi-mveliso kunye neenkqubo zonyango.

Imfuno yeMarike yoLuhlu lwe-DPL - Amathuba eMarike aKhulayo

Njengoko imfuno yee-laser ze-solid-state iqhubeka nokukhula kumashishini ahlukeneyo, ikwanjalo nesidingo semithombo yokupompa esebenza kakhulu njengeemodyuli ze-laser ze-CW diode-pumped. Amashishini afana nokuvelisa, ezempilo, ezokhuselo, kunye nophando lwesayensi axhomekeke kwii-laser ze-solid-state ukuze asetyenziswe ngokuchanekileyo.

Ngamafutshane, njengomthombo wokupompa we-diode we-laser eqinileyo, iimpawu zeemveliso: amandla okupompa anamandla aphezulu, imo yokusebenza ye-CW, umgangatho ogqwesileyo we-beam kunye nozinzo, kunye noyilo olucwangcisiweyo oluncinci, kwandisa imfuno yemarike kwezi modules ze-laser. Njengomthengisi, iLumispot Tech ikwazama kakhulu ukuphucula ukusebenza kunye nobuchwepheshe obusetyenziswa kuthotho lwe-DPL.

Iseti yeBundle yeMveliso ye-G2-A DPL evela kwiLumispot Tech

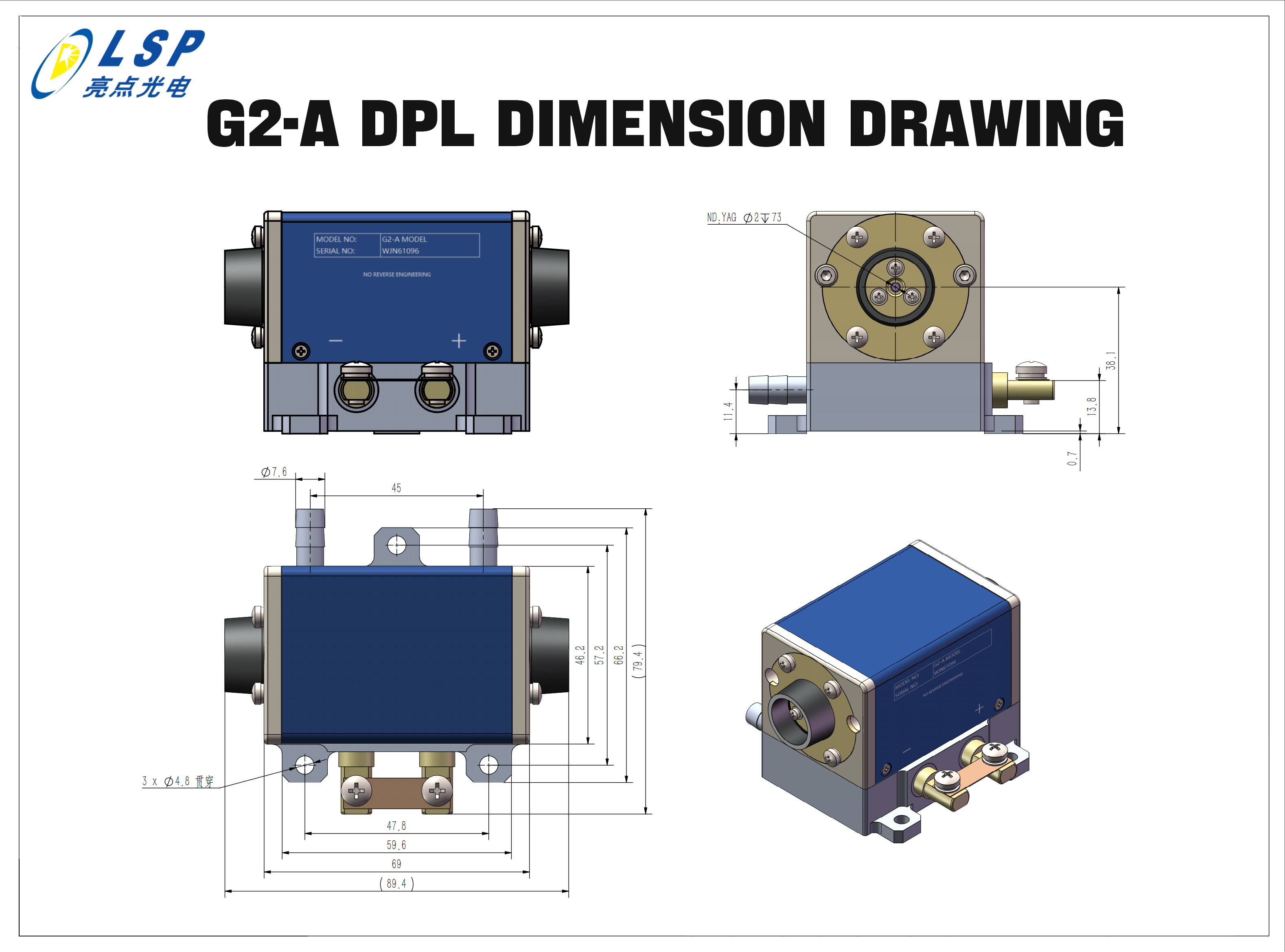

Iseti nganye yeemveliso inamaqela amathathu eemodyuli ze-array ezibekwe ngokuthe tye, iqela ngalinye leemodyuli ze-Horizontal Stacked Array ezimpompa amandla amalunga ne-100W@25A, kunye namandla okumpompa apheleleyo angama-300W@25A.

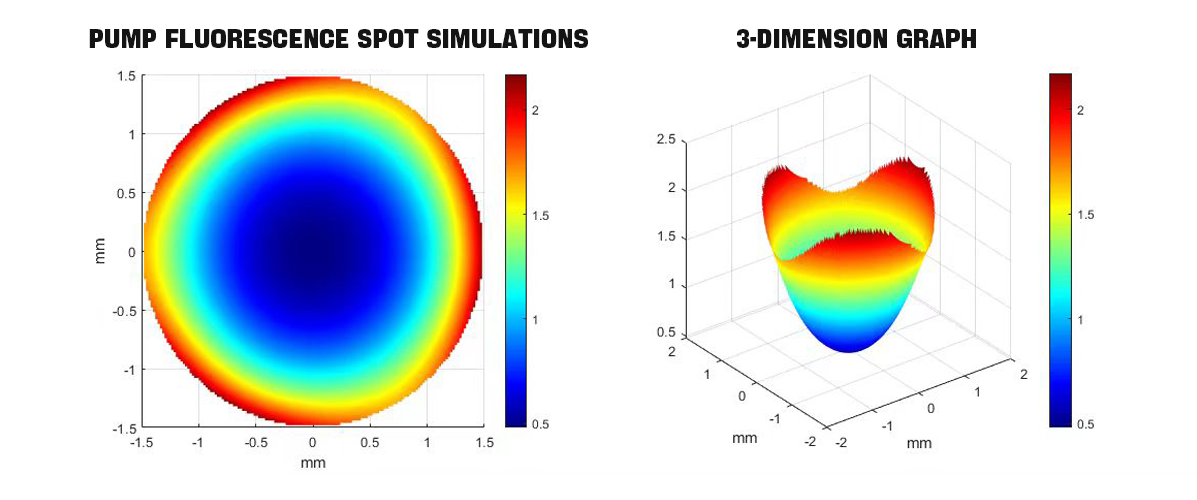

Indawo yokuqaqamba kwepompo ye-G2-A iboniswe ngezantsi:

Idatha yoBugcisa ephambili ye-G2-A Diode Pump Solid State Laser:

Amandla Ethu KwiTekhnoloji

1. Iteknoloji yoLawulo loBushushu oluThutyana

Iileser ze-solid-state ezifakwe i-semiconductor zisetyenziswa kakhulu kwizicelo ze-quasi-continuous wave (CW) ezine-high peak power output kunye ne-continuous wave (CW) ezine-avareji ephezulu yamandla. Kwezi leers, ukuphakama kwesinki yobushushu kunye nomgama phakathi kwee-chips (oko kukuthi, ubukhulu be-substrate kunye ne-chip) zichaphazela kakhulu amandla okusasaza ubushushu bemveliso. Umgama omkhulu we-chip-to-chip uphumela ekusasazekeni kobushushu okungcono kodwa unyusa umthamo wemveliso. Ngokwahlukileyo koko, ukuba isithuba se-chip sinciphile, ubungakanani bemveliso buya kuncitshiswa, kodwa amandla okusasaza ubushushu bemveliso anganelanga. Ukusebenzisa i-compact volume kakhulu ukuyila i-semiconductor-pumped solid-state laser efanelekileyo ehlangabezana neemfuno zokusasaza ubushushu ngumsebenzi onzima kuyilo.

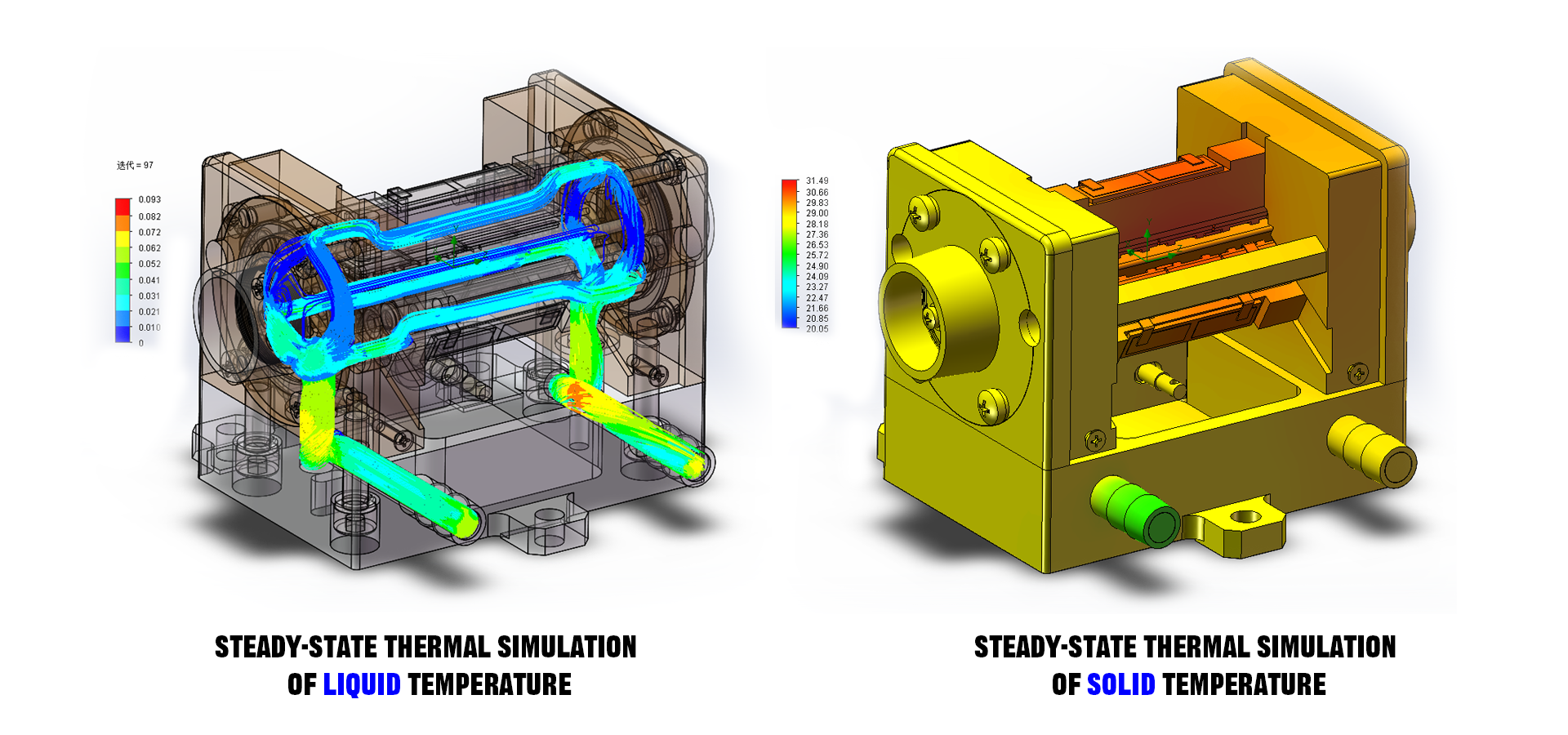

Igrafu yokulinganisa ubushushu obuzinzileyo

I-Lumispot Tech isebenzisa indlela ye-finite element ukulinganisa nokubala intsimi yobushushu yesixhobo. Kusetyenziswa indibaniselwano yokulinganisa ubushushu obuqinileyo kunye nokulinganisa ubushushu bolwelo ukuze kulinganiswe ubushushu. Kwiimeko zokusebenza eziqhubekayo, njengoko kubonisiwe kumfanekiso ongezantsi: imveliso icetywayo ukuba ibe nesithuba esifanelekileyo se-chip kunye nolungiselelo phantsi kweemeko zokulinganisa ubushushu obuqinileyo. Phantsi kwale sithuba kunye nolwakhiwo, imveliso inamandla okucoca ubushushu, ubushushu obuphantsi, kunye nophawu oluncinci kakhulu.

2.I-AuSn solderinkqubo yokugquma

I-Lumispot Tech isebenzisa indlela yokupakisha esebenzisa i-AnSn solder endaweni ye-indium solder yendabuko ukujongana nemiba enxulumene nokudinwa kobushushu, ukufuduka kwe-electromigration, kunye nokufuduka kombane-ubushushu okubangelwa yi-indium solder. Ngokusebenzisa i-AuSn solder, inkampani yethu ijolise ekuphuculeni ukuthembeka kwemveliso kunye nobude bayo. Olu tshintsho lwenziwa ngelixa kuqinisekiswa ukuba isithuba seebhari ezihlala zihleli, nto leyo enegalelo ekuphuculeni ukuthembeka kwemveliso kunye nobomi bayo.

Kwiteknoloji yokupakisha ye-laser ye-solid-state efakwe i-semiconductor enamandla aphezulu, i-indium (In) metal iye yamkelwe njengezinto zokuwelda ngabavelisi bamazwe ngamazwe ngenxa yeenzuzo zayo zokunyibilika okuphantsi, uxinzelelo oluphantsi lokuwelda, ukusebenza lula, kunye nokuguqulwa kweplastiki okuhle kunye nokungena. Nangona kunjalo, kwii-laser ze-solid state ezifakwe i-semiconductor phantsi kweemeko zokusebenza okuqhubekayo, uxinzelelo olutshintshanayo luya kubangela ukudinwa koxinzelelo lwe-indium welding layer, okuya kukhokelela ekungaphumeleli kwemveliso. Ingakumbi kumaqondo obushushu aphezulu naphantsi kunye nobubanzi be-pulse obude, izinga lokungaphumeleli kwe-indium welding licacile kakhulu.

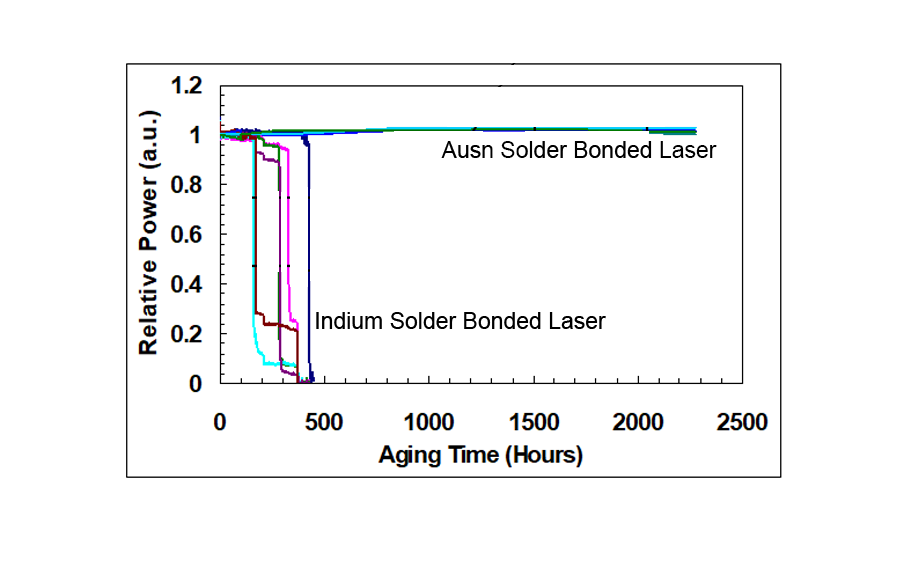

Uthelekiso lovavanyo lobomi olukhawulezisiweyo lwee-laser kunye neepakeji ezahlukeneyo ze-solder

Emva kweeyure ezingama-600 zokuguga, zonke iimveliso ezifakwe i-indium solder ziyasilela; ngelixa iimveliso ezifakwe i-gold tin zisebenza iiyure ezingaphezu kwama-2,000 ngaphandle kotshintsho kumandla; zibonisa iingenelo ze-AuSn encapsulation.

Ukuze kuphuculwe ukuthembeka kwee-laser ze-semiconductor ezinamandla aphezulu ngelixa kugcinwa ukuhambelana kwezalathisi ezahlukeneyo zokusebenza, iLumispot Tech isebenzisa iHard Solder (AuSn) njengohlobo olutsha lwezinto zokupakisha. Ukusetyenziswa kwe-coefficient yezinto ezihambelana ne-thermal expansion substrate (CTE-Matched Submount), ukukhululwa okusebenzayo koxinzelelo lobushushu, isisombululo esilungileyo kwiingxaki zobugcisa ezinokufunyanwa xa kulungiswa i-hard solder. Imeko efunekayo ukuze izinto ze-substrate (submount) zikwazi ukudityaniswa kwi-semiconductor chip kukwenziwa kwe-surface metallization. Ukwenziwa kwe-surface metallization kukwenziwa komaleko womqobo wokusasazwa kunye nomaleko wokungena kwe-solder kumphezulu wezinto ze-substrate.

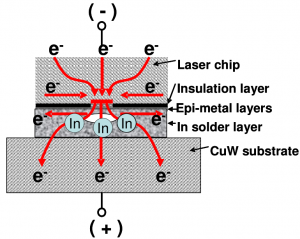

Umzobo weskimu wendlela yokufuduka kwe-electromigration ye-laser efakwe kwi-indium solder

Ukuze kuphuculwe ukuthembeka kwee-laser ze-semiconductor ezinamandla aphezulu ngelixa kugcinwa ukuhambelana kwezalathisi ezahlukeneyo zokusebenza, iLumispot Tech isebenzisa iHard Solder (AuSn) njengohlobo olutsha lwezinto zokupakisha. Ukusetyenziswa kwe-coefficient yezinto ezihambelana ne-thermal expansion substrate (CTE-Matched Submount), ukukhululwa okusebenzayo koxinzelelo lobushushu, isisombululo esilungileyo kwiingxaki zobugcisa ezinokufunyanwa xa kulungiswa i-hard solder. Imeko efunekayo ukuze izinto ze-substrate (submount) zikwazi ukudityaniswa kwi-semiconductor chip kukwenziwa kwe-surface metallization. Ukwenziwa kwe-surface metallization kukwenziwa komaleko womqobo wokusasazwa kunye nomaleko wokungena kwe-solder kumphezulu wezinto ze-substrate.

Injongo yayo kwelinye icala kukuthintela i-solder ukuya kwi-substrate material diffusion, kwelinye icala kukuqinisa i-solder ngamandla okuwelda izinto ze-substrate, ukuthintela umaleko we-solder we-cavity. I-surface metallization inokuthintela i-substrate material oxidation kunye nokungena komswakama, ukunciphisa ukumelana nokudibana kwinkqubo yokuwelda, kwaye ngaloo ndlela kuphuculwe amandla okuwelda kunye nokuthembeka kwemveliso. Ukusetyenziswa kwe-hard solder AuSn njengesixhobo sokuwelda kwi-semiconductor pumped solid state lasers kunokuthintela ngempumelelo ukudinwa kwe-indium stress, i-oxidation kunye ne-electro-thermal migration kunye nezinye iziphene, kuphucula kakhulu ukuthembeka kwe-semiconductor lasers kunye nobomi benkonzo ye-laser. Ukusetyenziswa kwetekhnoloji ye-gold-tin encapsulation kunokoyisa iingxaki ze-electromigration kunye ne-electrothermal migration ye-indium solder.

Isisombululo esivela kwiLumispot Tech

Kwi-laser eziqhubekayo okanye ezishukumayo, ubushushu obuveliswa kukufunxwa kwemisebe yepompo yi-laser medium kunye nokupholisa kwangaphandle kwe-medium kukhokelela kukusasazwa kobushushu obungalinganiyo ngaphakathi kwe-laser medium, okubangela ii-gradients zobushushu, okubangela utshintsho kwi-refractive index ye-medium kwaye emva koko kuvelise iziphumo ezahlukeneyo zobushushu. Ukufakwa kwe-thermal ngaphakathi kwe-gain medium kukhokelela kwisiphumo se-thermal lensing kunye nesiphumo se-birifringence esibangelwa yi-thermal, esivelisa ilahleko ezithile kwinkqubo ye-laser, echaphazela ukuzinza kwe-laser kwindawo kunye nomgangatho we-output beam. Kwinkqubo ye-laser esebenza rhoqo, uxinzelelo lwe-thermal kwi-gain medium luyatshintsha njengoko amandla epompo enyuka. Iziphumo ezahlukeneyo ze-thermal kwinkqubo zichaphazela kakhulu yonke inkqubo ye-laser ukufumana umgangatho ongcono we-beam kunye namandla aphezulu e-output, enye yeengxaki ekufuneka zisonjululwe. Indlela yokuthintela ngempumelelo kunye nokunciphisa isiphumo se-thermal se-crystals kwinkqubo yokusebenza, izazinzulu bezisoloko zikhathazekile ixesha elide, ibe yenye yezona ndawo ziphambili zophando zangoku.

I-Nd:YAG laser ene-thermal lens cavity

Kwiprojekthi yokuphuhlisa iilaser ze-Nd:YAG ezimpompiweyo ze-LD ezinamandla aphezulu, iilaser ze-Nd:YAG ezine-thermal lensing cavity zasonjululwa, ukuze imodyuli ifumane amandla aphezulu ngelixa ifumana umgangatho ophezulu we-beam.

Kwiprojekthi yokuphuhlisa i-laser ye-LD-pumped Nd:YAG enamandla aphezulu, iLumispot Tech iphuhlise imodyuli ye-G2-A, esombulula kakhulu ingxaki yamandla aphantsi ngenxa yemingxuma equlethe ilensi yobushushu, ivumela imodyuli ukuba ifumane amandla aphezulu ngomgangatho ophezulu wemitha.

Ixesha leposi: Julayi-24-2023