Kuyilo nakwimveliso yee-laser ze-semiconductor ezinamandla aphezulu, ii-laser diode bars zisebenza njengeeyunithi eziphambili zokukhupha ukukhanya. Ukusebenza kwazo akuxhomekanga kuphela kumgangatho wangaphakathi wee-laser chips kodwa nakwinkqubo yokupakisha. Phakathi kwezinto ezahlukeneyo ezibandakanyekayo ekupakisheni, izinto ze-solder zidlala indima ebalulekileyo njengomdibaniso wobushushu kunye nombane phakathi kwe-chip kunye nesinki yobushushu.

1. Indima yeSolder kwiLaser Diode Bars

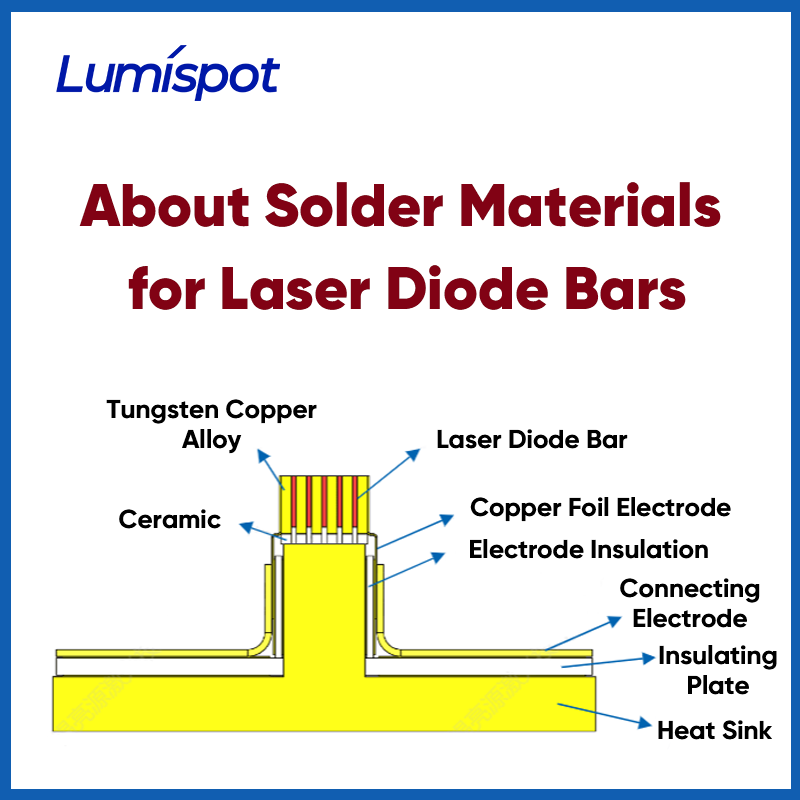

Iibha ze-laser diode zihlala zidibanisa ii-emitters ezininzi, nto leyo ebangela uxinano lwamandla aphezulu kunye neemfuno ezingqongqo zolawulo lobushushu. Ukuze kufezekiswe ukusasazwa kobushushu ngokufanelekileyo kunye nokuzinza kwesakhiwo, izinto ze-solder kufuneka zihlangabezane nezi khrayitheriya zilandelayo:

① Ukuqhuba okuphezulu kobushushu:

Iqinisekisa ukudluliselwa kobushushu okusebenzayo ukusuka kwi-chip yelaser.

② Ukufuma kakuhle:

Ibonelela ngokubopha okuqinileyo phakathi kwe-chip kunye ne-substrate.

③ Indawo efanelekileyo yokunyibilika:

Ithintela ukuphinda kuphume okanye ukuwohloka ngexesha lokucubungula okanye ukusebenza okulandelayo.

④ I-coefficient ehambelanayo yokwandiswa kobushushu (CTE):

Inciphisa uxinzelelo lobushushu kwitshiphusi.

⑤ Ukumelana nokudinwa okugqwesileyo:

Yandisa ubomi benkonzo yesixhobo.

2. Iindidi eziqhelekileyo zeSolder zokuPakisha iLaser Bar

Ezi zilandelayo ziintlobo ezintathu eziphambili zezinto zokufaka i-solder ezisetyenziswa kakhulu ekupakisheni iibha ze-laser diode:

①I-Alloy yeGold-Tin (AuSn)

Iipropati:

Ukwakheka kwe-Eutectic kwe-80Au/20Sn kunye nendawo yokunyibilika ye-280°C; ukuhanjiswa kobushushu okuphezulu kunye namandla oomatshini.

Iingenelo:

Uzinzo oluhle kakhulu kumaqondo obushushu aphezulu, ubomi obude bokudinwa kubushushu, akukho ngcoliseko lwezinto eziphilayo, ukuthembeka okuphezulu

Izicelo:

Iinkqubo zelaser zomkhosi, zeenqwelo moya, kunye neenkqubo zelaser zoshishino ezikumgangatho ophezulu.

②I-Indium ecocekileyo (ngaphakathi)

Iipropati:

Iqondo lokunyibilika le-157°C; lithambile kwaye lithambile kakhulu.

Iingenelo:

Ukusebenza kakuhle kokujikeleza kobushushu, uxinzelelo oluphantsi kwitshiphu, ilungele ukukhusela izakhiwo ezibuthathaka, ifanelekile kwiimfuno zokubopha eziphantsi kobushushu

Imida:

Ithanda ukubola; ifuna umoya ongasebenziyo ngexesha lokucubungula, amandla aphantsi oomatshini; ayifanelekanga ukusetyenziswa kwimithwalo ephezulu

③Iinkqubo ze-Composite Solder (umz., AuSn + In)

Ulwakhiwo:

Ngokwesiqhelo, i-AuSn isetyenziswa phantsi kwetshiphu ukuze inamathele ngokuqinileyo, ngelixa i-In isetyenziswa phezulu ukuze iphucule ukuxinana kobushushu.

Iingenelo:

Idibanisa ukuthembeka okuphezulu kunye nokunciphisa uxinzelelo, iphucula ukuqina kokupakishwa ngokubanzi, iyaziqhelanisa kakuhle neendawo ezahlukeneyo zokusebenza

3. Impembelelo yoMgangatho weSolder ekusebenzeni kweSixhobo

Ukukhethwa kwezinto ezithengiswayo kunye nolawulo lwenkqubo kuchaphazela kakhulu ukusebenza kwe-electro-optical kunye nokuzinza kwexesha elide kwezixhobo ze-laser:

| I-Solder Factor | Impembelelo kwiSixhobo |

| Ukufana komaleko we-Solder | Ichaphazela ukusasazwa kobushushu kunye nokuhambelana kwamandla okukhanya |

| Umlinganiselo ongenanto | Izithuba eziphezulu zikhokelela ekuchaseni ubushushu okwandayo kunye nobushushu obugqithisileyo bendawo ethile |

| Ubumsulwa be-alloy | Iimpembelelo zokunyibilikisa uzinzo kunye nokusasazwa kwe-intermetallic |

| Ukumanzika kobuso | Imisela amandla okubopha kunye nokuqhuba kobushushu bomphezulu |

Xa kusetyenzwa ngamandla amakhulu rhoqo, nokuba zizinto ezincinci ekufakweni kwe-soldering zingakhokelela ekukhuleni kobushushu, nto leyo ekhokelela ekuwohlokeni kokusebenza okanye ekusileleni kwesixhobo. Ke ngoko, ukukhetha i-solder esemgangathweni ophezulu kunye nokusebenzisa iinkqubo ezichanekileyo zokutywina kubalulekile ekufezekiseni upakisho lwe-laser oluthembekileyo.

4. Iindlela kunye noPhuhliso lwexesha elizayo

Njengoko ubuchwepheshe be-laser buqhubeka nokungena kwiinkqubo zoshishino, utyando lwezonyango, i-LiDAR, kunye nezinye iinkalo, izixhobo ze-solder zokupakisha i-laser ziyavela ngale ndlela ilandelayo:

①Ukutywina okuphantsi kobushushu:

Ukudibanisa nezinto ezinobuzwelo kubushushu

②Isoda engenalo ilothe:

Ukuhlangabezana neRoHS kunye neminye imimiselo yokusingqongileyo

③Izixhobo zojongano lobushushu obuphezulu (i-TIM):

Ukunciphisa ngakumbi ukumelana nobushushu

④Iitekhnoloji zokudibanisa izinto ezincinci:

Ukuxhasa ukwenziwa kwezinto ezincinci kunye nokuhlanganiswa koxinano oluphezulu

5. Isiphelo

Nangona zincinci ngomthamo, izinto ze-solder zezona ziqhagamshelo zibalulekileyo eziqinisekisa ukusebenza kunye nokuthembeka kwezixhobo ze-laser ezinamandla aphezulu. Kwiphakheji yeebha ze-laser diode, ukukhetha i-solder efanelekileyo kunye nokwenza ngcono inkqubo yokubopha kubalulekile ekufezekiseni ukusebenza okuzinzileyo kwexesha elide.

6. Ngathi

I-Lumispot izibophelele ekuboneleleni abathengi ngezixhobo zelaser zobungcali nezithembekileyo kunye nezisombululo zokupakisha. Ngamava amaninzi ekukhetheni izinto ze-solder, uyilo lolawulo lobushushu, kunye novavanyo lokuthembeka, sikholelwa ukuba yonke ingcaciso eneenkcukacha ivula indlela eya ekugqweseni. Ukuze ufumane ulwazi oluthe kratya malunga netekhnoloji yokupakisha yelaser enamandla aphezulu, zive ukhululekile ukunxibelelana nathi.

Ixesha leposi: Julayi-07-2025