Bhalisela kwiMidiya yethu yeNtlalo ukuze ufumane iPosi ekhawulezileyo

Kwimveliso yezixhobo zelaser ezichanekileyo, ukulawula okusingqongileyo kubalulekile. Kwiinkampani ezifana neLumispot Tech, egxile ekuveliseni iilaser ezikumgangatho ophezulu, ukuqinisekisa ukuba indawo yokuvelisa engenaluthuli ayisiyonto iqhelekileyo nje kuphela—kukuzinikela kumgangatho kunye nokwaneliseka kwabathengi.

Yintoni isuti yegumbi lokucoca?

Ingubo yegumbi lokucoca, eyaziwa ngokuba yisuti yegumbi lokucoca, isuti yemvundla, okanye izambatho, yimpahla ekhethekileyo eyenzelwe ukunciphisa ukukhutshwa kwezinto ezingcolisayo kunye namasuntswana kwindawo yegumbi lokucoca. Iigumbi lokucoca ziindawo ezilawulwayo ezisetyenziswa kwiinkalo zesayensi kunye nezoshishino, ezifana nokuvelisa i-semiconductor, i-biotechnology, amayeza, kunye ne-aerospace, apho amanqanaba aphantsi okungcola njengothuli, iintsholongwane ezibhabha emoyeni, kunye namasuntswana e-aerosol abalulekile ekugcineni umgangatho kunye nokuthembeka kweemveliso.

Abasebenzi be-R&D eLumispot Tech

Kutheni Kufuneka Iimpahla Zokucoca:

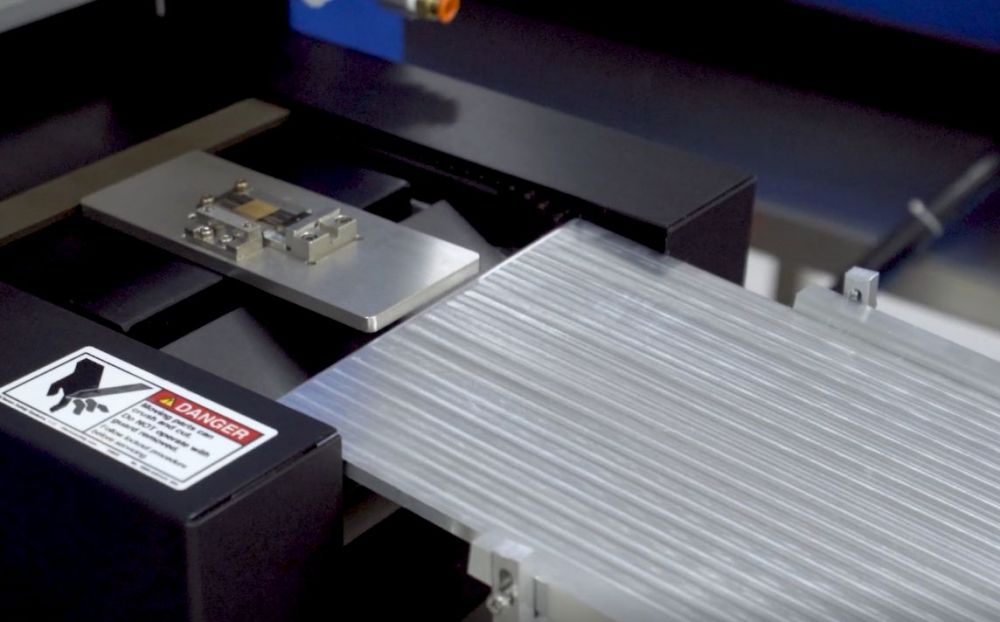

Ukususela ekusekweni kwayo ngo-2010, iLumispot Tech iqalise umgca wemveliso ophucukileyo, ongenaluthuli olusemgangathweni wemizi-mveliso ngaphakathi kwesakhiwo sayo esingange-14,000-square-foot. Bonke abasebenzi abangena kwindawo yemveliso kufuneka banxibe iimpahla zokucoca ezihambelana nemigangatho eqhelekileyo. Olu qheliselo lubonisa ulawulo lwethu olungqongqo lomgangatho kunye nengqalelo kwinkqubo yokuvelisa.

Ukubaluleka kweempahla ezingenathuli kwindawo yokusebenzela kubonakala kakhulu kwezi zinto zilandelayo:

Igumbi lokucoca eLumispot Tech

Ukunciphisa Umbane Ongashukumiyo

Amalaphu akhethekileyo asetyenziswa kwiimpahla zegumbi lokucoca adla ngokuquka imisonto eqhuba umbane ukuthintela ukwakheka kombane ongashukumiyo, ongonakalisa izinto ezibuthathaka ze-elektroniki okanye ukutshisa izinto ezivuthayo. Uyilo lwezi mpahla luqinisekisa ukuba umngcipheko wokukhutshwa kwe-electrostatic discharge (ESD) uyancitshiswa (Chubb, 2008).

Ulawulo loNgcoliseko:

Izambatho zegumbi lokucoca zenziwe ngelaphu elikhethekileyo elithintela ukuchitheka kweefayibha okanye amasuntswana kwaye lixhathise ukuqokelelana kombane ongashukumiyo onokutsala uthuli. Oku kunceda ukugcina imigangatho yococeko engqongqo efunekayo kumagumbi okucoca apho amasuntswana amancinci anokubangela umonakalo omkhulu kwi-microprocessors, ii-microchips, iimveliso zamayeza, kunye nezinye iiteknoloji ezinobukrelekrele.

Ukunyaniseka kweMveliso:

Kwiinkqubo zokuvelisa apho iimveliso zichaphazeleka kakhulu kungcoliseko lokusingqongileyo (njengokwenziwa kwe-semiconductor okanye ukuveliswa kwamayeza), iimpahla zokucoca zinceda ukuqinisekisa ukuba iimveliso ziveliswa kwindawo engenangcoliseko. Oku kubalulekile ekusebenzeni nasekuthembekeni kwezinto zobugcisa obuphezulu kunye nokhuseleko lwempilo kumayeza.

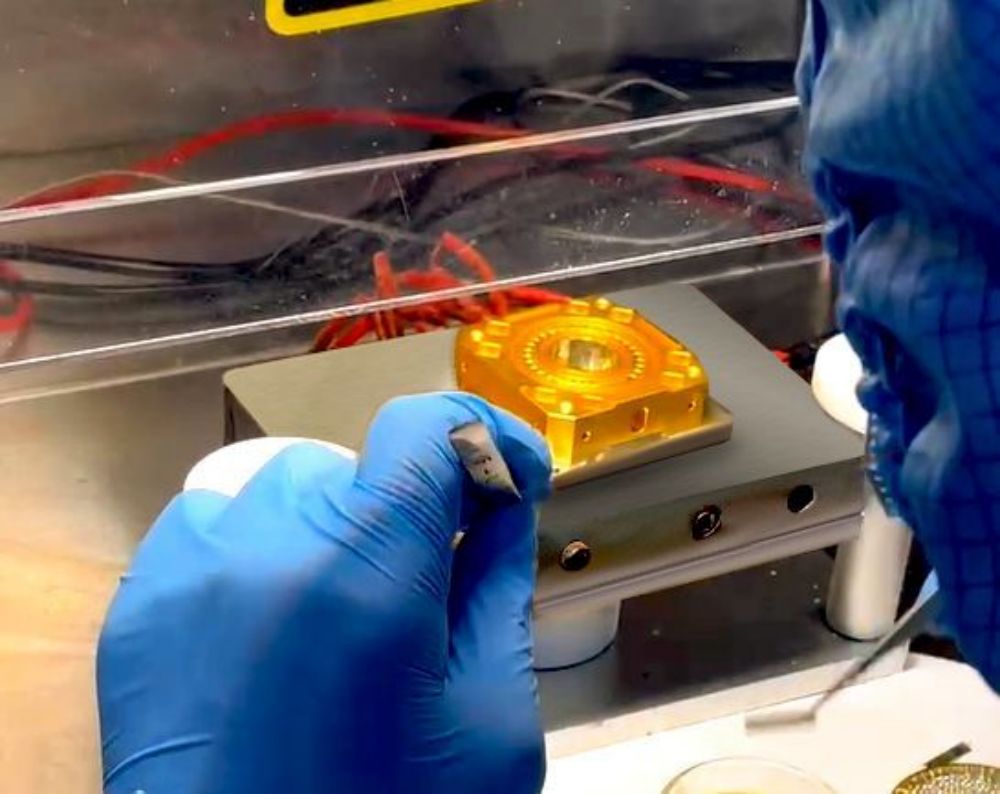

Iingcali zeLumispotI-Laser Diode Bar ArrayInkqubo yoMveliso

Ukhuseleko kunye nokuThotyelwa kweMithetho:

Ukusetyenziswa kweempahla zokucoca kukwafuneka ngokwemigangatho emiselweyo yimibutho efana ne-ISO (International Organisation for Standardization) ehlela amagumbi okucoca ngokusekelwe kwinani lamasuntswana avumelekileyo nge-cubic meter yomoya. Abasebenzi abakwiigumbi zokucoca kufuneka banxibe ezi mpahla ukuze bahambelane nale migangatho kwaye baqinisekise ukhuseleko lwemveliso kunye nabasebenzi, ngakumbi xa bephatha izinto ezinobungozi (Hu & Shiue, 2016).

Uhlu lweeMpahla zeGumbi lokucoca

Amanqanaba oHlelo: Iimpahla zegumbi lokucoca ziqala kwiiklasi eziphantsi ezifana neKlasi 10000, ezifanelekileyo kwiindawo ezingqongqo kangako, ukuya kwiiklasi eziphezulu ezifana neKlasi 10, ezisetyenziswa kwiindawo ezibuthathaka kakhulu ngenxa yokukwazi kwazo ukulawula ungcoliseko lweenxalenye ezithile (Boone, 1998).

Iimpahla zeKlasi 10 (ISO 3):Ezi mpahla zifanelekile kwiindawo ezifuna ucoceko oluphezulu, njengokuveliswa kweenkqubo ze-laser, iifayibha ze-optical, kunye ne-precision optics. Iimpahla ze-Class 10 zithintela ngempumelelo amasuntswana amakhulu kune-0.3 micrometers.

Iimpahla zeKlasi 100 (ISO 5):Ezi mpahla zisetyenziswa ekuveliseni izinto ze-elektroniki, izibonisi zephaneli ezisicaba, kunye nezinye iimveliso ezifuna ucoceko oluphezulu. Iimpahla zeKlasi 100 zinokuvala amasuntswana amakhulu kune-0.5 micrometers.

Iimpahla zeKlasi 1000 (ISO 6):Ezi mpahla zifanelekile kwiindawo ezineemfuno zococeko oluphakathi, njengokuveliswa kwezinto ze-elektroniki kunye nezixhobo zonyango.

Iimpahla zeKlasi 10,000 (ISO 7):Ezi mpahla zisetyenziswa kwiindawo zoshishino ngokubanzi apho kukho imfuneko ephantsi yokucoceka.

Iimpahla zokucoca zihlala ziquka ii-hood, iimaski zobuso, izihlangu, ii-coveralls, kunye neeglavu, zonke zenzelwe ukugubungela ulusu oluvezwe phandle kangangoko kunokwenzeka kwaye zithintele umzimba womntu, ongumthombo omkhulu wezinto ezingcolisayo, ekungeniseni amasuntswana kwindawo elawulwayo.

Ukusetyenziswa kwiiWorkshops zeOptical kunye neLaser Production

Kwiimeko ezifana ne-optics kunye ne-laser production, iimpahla ze-cleanroom zihlala zifuna ukuhlangabezana nemigangatho ephezulu, ngokuqhelekileyo i-Class 100 okanye i-Class 10. Oku kuqinisekisa ukuphazamiseka okuncinci kwamasuntswana kwiinxalenye ze-optical ezinobuthathaka kunye neenkqubo ze-laser, nto leyo enokubangela imiba ebalulekileyo yomgangatho kunye nokusebenza (Stowers, 1999).

Abasebenzi kwiLumispot Tech abasebenza kwiQCWIi-Annular Laser Diode stacks.

Ezi mpahla zegumbi lokucoca zenziwe ngamalaphu akhethekileyo angenazimo eziqinileyo anika uthuli oluhle kakhulu kunye nokumelana okungashukumiyo. Uyilo lwale mpahla lubalulekile ekugcineni ucoceko. Iimpawu ezifana neecuffs kunye namaqatha aqinileyo, kunye neeziphu ezifikelela kwikhola, zisetyenziswa ukwandisa umqobo nxamnye nongcoliseko olungena kwindawo ecocekileyo.

Isalathiso

Boone, W. (1998). Uvavanyo lwamalaphu eempahla zegumbi lokucoca/ESD: iindlela zovavanyo kunye neziphumo. Iinkqubo zeSimposium ye-Electrical Overstress/Electrostatic Discharge. 1998 (Cat. No.98TH8347).

Stowers, I. (1999). Iinkcukacha zococeko lwamehlo kunye nokuqinisekiswa kococeko. Iinkqubo ze-SPIE.

Chubb, J. (2008). Izifundo zeTribocharging kwiimpahla ezihlalwa ngabantu. Ijenali yeElectrostatics, 66, 531-537.

Hu, S.-C., & Shiue, A. (2016). Ukuqinisekiswa kunye nokusetyenziswa kwento efunekayo kubasebenzi kwimpahla esetyenziswa kwiindawo zokucoca. Isakhiwo kunye neNdalo.

Ixesha leposi: Epreli-24-2024